Introduction

Aluminum wire bonding has emerged as a important approach inside the realm of electronics manufacturing, peculiarly throughout the semiconductor trade. As era advances, the desire for environment friendly, risk-free programs of connecting chips to substrates will become ever greater paramount. This article delves into aluminum twine bonding, exploring its techniques, programs, reward, demanding situations, and destiny trends. By understanding these points, professionals can make proficient judgements on the topic of their cord bonding tactics and methods.

Aluminum Wire Bonding: Methods and Applications

What is Wire Bonding?

Wire bonding refers to a greatly used interconnect process that creates electric connections between microelectronic gadgets and their substrates. The process includes as a result of thin wires—probably made from gold, aluminum, or copper—to determine those connections. It performs a a must have role in semiconductor packaging and is basic for making sure that electronic gadgets goal without problems.

Understanding the Wire Bonding Process

The cord bonding approach can be broken down into quite a few key steps:

Preparation: This consists of cleansing the bonding pads on the two the chip and substrate to be certain that top-quality adhesion. Positioning: The bond device positions the twine above the precise field on the substrate or chip. Bond Formation: Depending on the method used (ball bonding or wedge bonding), warmth, ultrasonic calories, or power is utilized to model a amazing bond. Loop Formation: If required, a loop is formed with the bonding twine to deal with movement and thermal growth. Trimming: Excess cord is trimmed to finalize the bond.Types of Wire Bonding Techniques

When it involves wire bonding concepts, countless systems stand out:

- Ball Bonding: Utilizes a small ball at the finish of the twine created via heating it; suitable for quality-pitch applications. Wedge Bonding: Employs a wedge-formed device to create bonds; fantastic for thicker wires. Ribbon Bonding: Involves with the aid of flat ribbon-like wires for prime-density programs.

Each components has its pleasing benefits depending on venture requirements.

Wire Bonding Equipment Overview

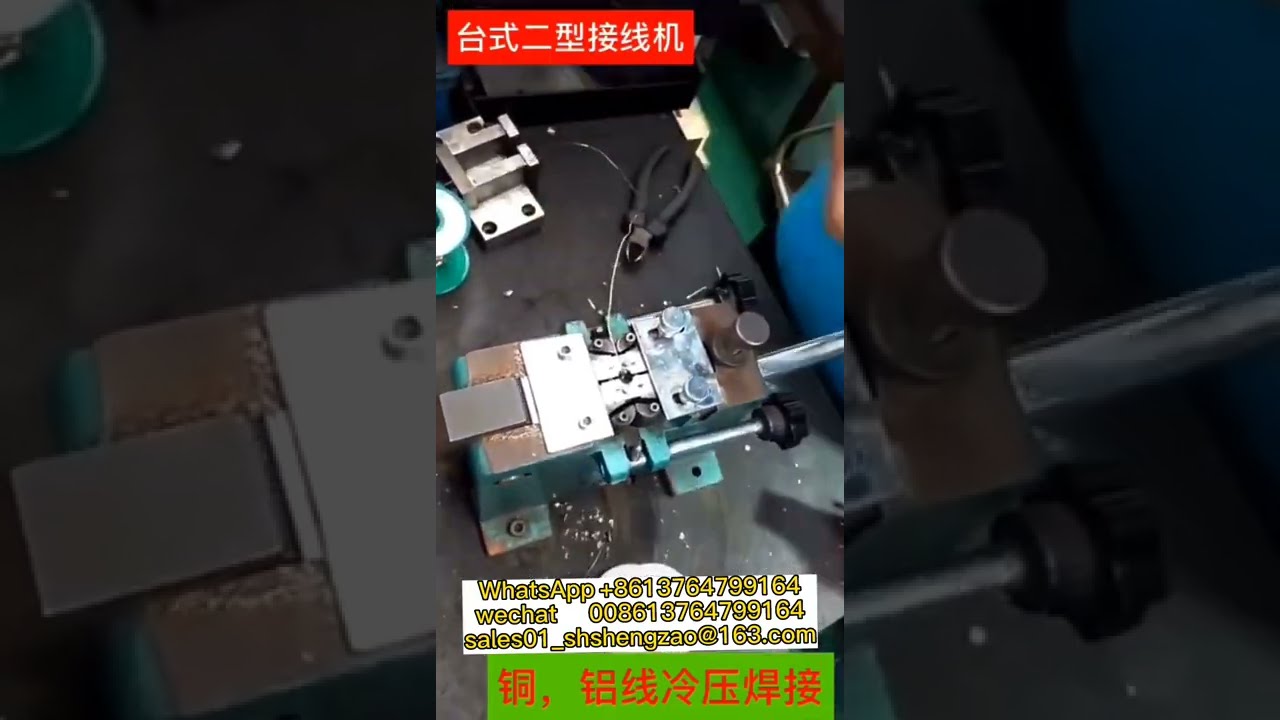

Wire Bonding Machines

Wire bonding machines are specialized machinery designed to automate the wire bonding procedure. Key functions more often than not incorporate programmable settings for totally different parameters consisting of temperature and drive.

Manual vs Automatic Wire Bonding Machines

While handbook machines give flexibility and manage over small batches, computerized machines be offering effectivity for prime-volume creation. The choice widely relies on construction necessities.

Applications of Aluminum Wire Bonding in Electronics

Aluminum wire bonding finds good sized functions in different sectors:

- Semiconductors: Essential for connecting built-in circuits (ICs) on silicon wafers. Automotive Electronics: Used in sensors and management sets as a result of its reliability below various circumstances. Medical Devices: Critical for making certain toughness in life-saving gadget.

These programs exhibit aluminum's versatility in meeting revolutionary digital calls for.

Aluminum vs Gold Wire Bonding

When it involves comparing aluminum cord bonding with gold cord bonding:

| Feature | Aluminum Wire Bonding | Gold Wire Bonding | |--------------------------|-----------------------|--------------------| | Cost | Lower | Higher | | Oxidation Resistance | Moderate | Excellent | | Thermal Conductivity | Good | Excellent | | Usage | High volume | Specialty |

Aluminum gives you settlement-effectiveness at the same time gold grants most appropriate efficiency in phrases of oxidation resistance.

Challenges in Aluminum Wire Bonding

Despite its advantages, aluminum wire bonding gifts challenges:

Oxidation Issues: Aluminum can oxidize immediately; for that reason relevant cleaning is basic prior to bonding. Bond Reliability: Variations in environmental stipulations can impression bond energy over time. Quality Control: Ensuring steady good quality requires rigorous inspection protocols.Addressing these challenges is valuable for protecting reliability in electronic method.

Wire Bonding Failure Analysis

Failure diagnosis in cord bonding comprises examining faulty bonds to establish their root reasons—be it illness or wrong handling right through manufacturing.

Wire Bond Reliability Testing Methods

To be sure bond reliability, brands employ assorted testing processes:

Pull Test: Measures bond power by way of pulling on bonded wires until they holiday. Shear Test: Determines how good bonds withstand shear forces by way of applying lateral pressure. X-ray Inspection: Non-unfavourable trying out components that reveals structural integrity with out unfavorable substances.These assessments are very important for high quality insurance.

Future Trends in Aluminum Wire Bonding Technology

As generation evolves, so does aluminum twine bonding:

- Innovative Materials: Research into new alloys would advance performance and decrease quotes additional. Automation Advances: Enhanced automation will streamline processes while bettering precision. Miniaturization: As gadgets get smaller, techniques will preserve evolving towards finer pitches and tighter tolerances.

This continual evolution ensures that aluminum is still proper amidst changing technological landscapes.

Conclusion

In precis, aluminum wire bonding plays an imperative role in revolutionary electronics production by its distinctive methods and wide-ranging programs. Understanding its strategies—from styles of processes hired to demanding situations confronted—facilitates engineers and manufacturers alike to harness its full power successfully.

FAQs

1. What are the most styles of fabrics used in wire bonding?

The regular resources used are gold, aluminum, copper, and silver by way of their conductive properties and differing prices related to each material %%!%%b13e7619-0.33-416d-8bd7-0401a711c3f5%%!%%.

2. How does thermosonic ball bonding range from different approaches?

Thermosonic ball bonding combines warmness with ultrasonic vigour in the course of bond formation; this contrasts with purely mechanical or thermal techniques found in different procedures similar to wedge or ribbon bonding.

3. What points outcomes bond reliability?

Factors contain environmental situations (like humidity), textile houses (which include oxidation resistance), bond pad layout (dimension/tolerance), and relevant machinery calibration throughout construction runs.

4. Can I automate my existing guide wire-bond processes?

Yes! Transitioning from handbook techniques aas a rule calls for investing in programmable automatic machines which might greatly build up throughput at the same time as cutting back errors associated with human handling.

5. What inspections ought to be carried out submit-cord bonding?

Common inspections contain visual assessments (for noticeable defects), pull/shear checking out (to evaluate bond capability), x-ray inspections (for inside trouble), alongside environmental trying out if useful based totally on utility standards.

6. How do I go with among gold vs aluminum for my utility?

Consider elements like expense constraints as opposed to overall performance wants; if oxidation resistance isn’t essential yet budget constraints exist—aluminum may just suffice—whereas gold matches prime-performance scenarios requiring gold standard reliability.

This complete dialogue on "Aluminum Wire Bonding: Visit this website Methods and Applications" serves as each a ebook and reference point for these seeking to deepen their understanding of this imperative technological know-how inside of electronics production at the present time!