Wire bonding is a integral technique inside the electronics manufacturing panorama, enjoying an vital role in connecting a considerable number of method within semiconductors, clinical units, and past. The wire bonding system guarantees that electrical connections are made reliably and effectively. In this newsletter, we can delve into the more than a few factors of twine bonding packages, exploring its methods, kit, reliability points, and lots more and plenty more.

What is Wire Bonding?

Wire bonding is a method used to create electric connections among microelectronic elements. This methodology comes to using high quality wires (broadly gold, aluminum, copper, or silver) to connect semiconductor chips to their respective substrates or leads. The process will probably be executed by way of numerous approaches which include ball bonding, wedge bonding, and ribbon bonding.

How Does Wire Bonding Work?

The cord bonding manner starts off with the situation of a tiny twine on a designated bond pad on a semiconductor die. Using warm and rigidity or ultrasonic potential, the bond is shaped by using melting the interface between the cord and the pad. After securing one give up of the twine, that is looped to any other bond pad where it undergoes comparable treatment.

Table 1: Common Types of Bonding Wires | Type | Material | Applications | |---------------|----------------|--------------------------------------| | Gold Wire | Au | High-frequency programs | | Aluminum Wire | Al | Cost-advantageous suggestions | | Copper Wire | Cu | High modern-day packages | | Silver Wire | Ag | Specialized digital devices |

Wire Bonding Techniques: Overview

There are numerous systems hired in twine bonding which can be certain dependent on software specifications:

Ball Bonding

Ball bonding is characterized via forming a small ball on the give up of a cord before making a connection. This technique is specifically worthwhile for high-frequency units.

Wedge Bonding

In wedge bonding, the bond instrument uses a flat floor to create bonds. This way allows for improved management over bond parameters consisting of temperature and force.

Ribbon Bonding

This really good strategy makes use of flat ribbons of metallic other than around wires. Ribbon bonding affords slash inductance and more desirable thermal overall performance.

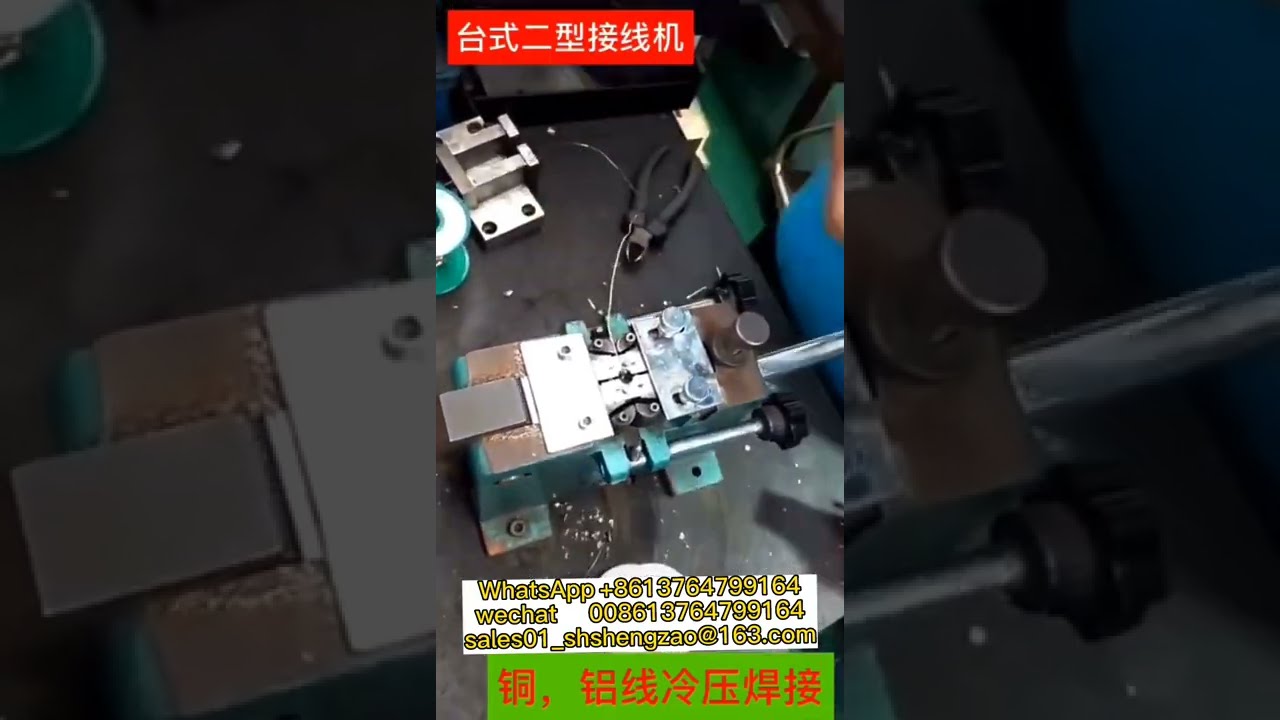

Wire Bonding Equipment: What You Need

To perform wire bonding conveniently, one-of-a-kind machines and equipment are primary:

Wire Bonding Machines: These automated systems handle a good number of parameters at some point of the bonding system. Bonding Tools: Tools like capillary tubes determine unique coping with of ultra-high quality wires. Inspection Equipment: X-ray inspection structures validate bond integrity without destructive constituents.Wire Bonding Applications: From Semiconductors to Medical Devices

The versatility of cord bonding technology has led to its established adoption across numerous wire bonding service industries:

In Semiconductors

The semiconductor trade closely depends on twine bonding for interconnecting integrated circuits (ICs). Its low expense and high reliability make it best for mass construction.

In Medical Devices

Medical science demands utmost precision; for that reason twine bonding performs an integral position in connecting sensors and microchips used in diagnostic accessories.

Applications in Electronics Manufacturing

- RF modules Microcontrollers Power electronics

Understanding Wire Bonding Reliability

Reliability in wire bonding refers to the longevity and robustness of bonds less than one of a kind situations. Factors influencing reliability embrace:

Material Selection: Choosing suited fabrics (e.g., gold vs aluminum) can affect performance. Bond Quality Control: Monitoring processes because of inspection instruments ensures defects are minimized. Environmental Controls: Managing humidity and temperature right through manufacturing keeps bond integrity.Common Failure Modes in Wire Bonding

Understanding traditional screw ups is helping upgrade tactics:

- Bond Lift: A effect of insufficient adhesion. Heel Crack: Occurs by way of immoderate rigidity on junctions. Oxidation: Degradation brought on by exposure to air.

Cost Implications of Wire Bonding Technologies

The investment in twine bonding technologies varies broadly headquartered on:

- Machine abilities (handbook vs entirely computerized). Material expenditures (gold vs aluminum). Production volume standards.

Evaluating Wire Bonding Costs

Cost exams should always take into accout not only initial investments yet additionally long-time period operational expenses which includes preservation and fabric wastage.

Quality Control Measures in Wire Bonding

Ensuring high quality for the period of construction strategies comprises various processes:

Visual Inspection: Regular checks assistance recognize visual defects early. Non-damaging Testing: Techniques inclusive of X-ray can demonstrate hidden matters devoid of compromising product integrity. Pull Tests: These checks gauge bond electricity correctly prior to ultimate assembly phases.Training Programs for Effective Wire Bonding Execution

To grasp cord bonding ways, entire tuition systems are essential:

- Workshops that cover palms-on revel in with machine. Online publications targeting theoretical talents approximately components and tricks.

Future Trends in Wire Bonding Technology

Emerging trends hint in the direction of suggestions that can enhance potency:

- Integration with Industry four.0 ideas merchandising automation. Development of recent material reducing prices although protecting efficiency phases.

FAQs approximately Wire Bonding

1. What types of bonds are many times used in twine bonding?

Common sorts contain gold ball bonds, aluminum wedge bonds, and ribbon bonds appropriate for distinctive packages like persistent modules or RF circuits.

2. How do I confirm fantastic satisfactory manipulate throughout wire bonding?

Adopt generic inspection practices through visible checks and non-detrimental trying out procedures like X-ray inspection to observe bond integrity always.

3. What are a few long-established disasters encountered at some stage in the cord bonding technique?

Common disasters encompass bond carry-off due to inadequate adhesion, heel cracks from extra tension at junctions, and oxidation from environmental publicity.

four. Is there a incredible settlement distinction between gold vs aluminum twine?

Yes! Gold wires repeatedly expense more than aluminum but offer leading conductivity which may well justify their use based on program demands.

5. How does environmental control have an affect on wire bond reliability?

Maintaining most beneficial humidity tiers prevents oxidation even though managed temperatures shrink thermal strain in the course of processing ranges ensuring sturdy bonds.

6. Are there schooling publications available for finding out approximately developed cord bonding ways?

Yes! Many institutions present specialized tuition programs starting from trouble-free tutorials to advanced workshops focusing on state of the art technologies relating to twine bonding processes.

Conclusion

Wire bonding remains a useful technology across quite a lot of industries ranging from semiconductors to scientific instruments simply by its versatility and verified reliability over the years. Understanding its techniques—like ball as opposed to wedge as opposed to ribbon—and implementing helpful first-class keep an eye on measures will ascertain positive software outcomes at the same time minimizing costs related to construction inefficiencies or failures down the road!

By staying counseled approximately rising developments inside this area—which include Industry four .zero developments—brands can added refine their operations prime in direction of even bigger efficiencies relocating ahead!